6 February 2023

Personalized drug discovery at lightspeed

Single-cell microfluidics + deep biological expertise + data intelligence = new paradigm

Components that pack a punch

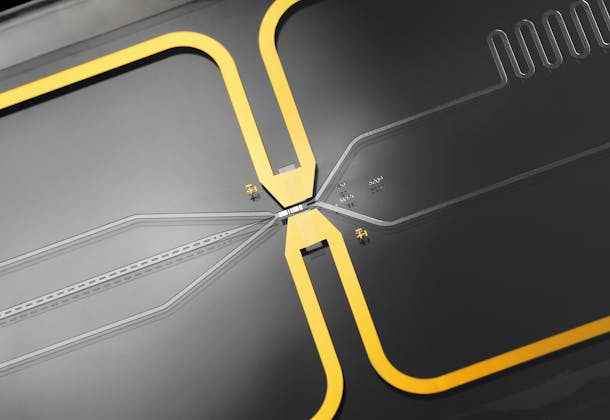

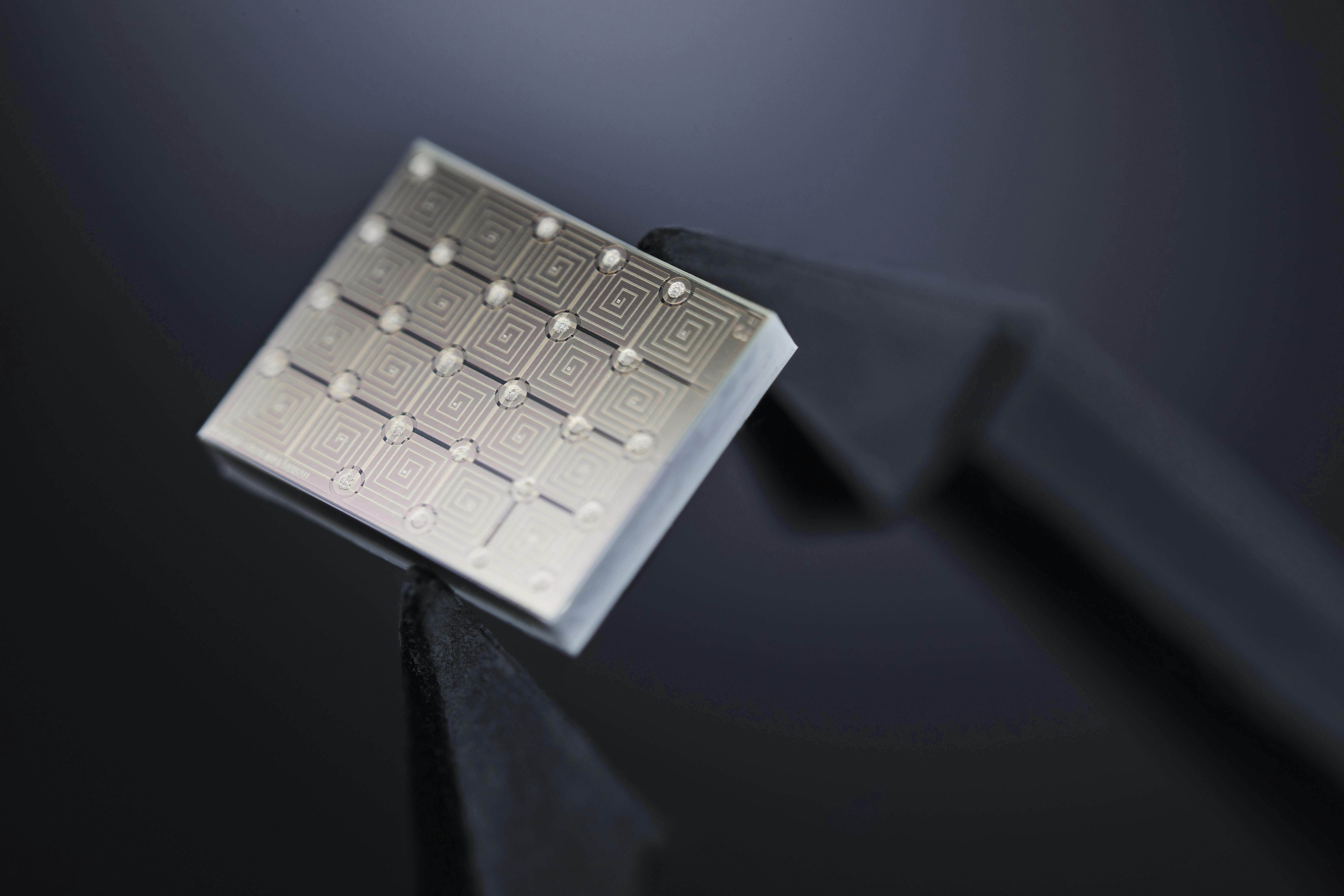

If silicon microprocessors are the brains of our car, phone, or virtual reality headset, MEMS give them their five senses. Sharing the same manufacturing principles, microfluidics and photonic components are set to disrupt entire industries in the coming years. MEMS and their manufacturing processes are a foundation of many 21st technologies yet remain largely unnoticed by the everyday user.

Within our MEMS powerhouse, we develop and industrialize processes for emerging materials and devices. Thanks to our multidisciplinary team, we offer a one-stop-shop for the entire innovation chain while meeting ISO 9001 standards.

We facilitate and accelerate the adoption of new processes and materials in microfabrication technologies. Our favorite playfield? High-added-value applications with demanding specifications.

> MEMS foundry services: We develop, industrialize, and produce microsystems for customers worldwide. With our lab-to-fab activities, we mature and kickstart the production of your prototypes.

> MEMS characterization and reliability testing: Our state-of-the art characterization lab is accredited by the European Space Agency for the toughest tests. We combine a deep understanding of materials with testing rigor to offer the best results to our clients.

Every industry and business can benefit from our expertise in MEMS and packaging. From smartphones to smart watches; from automobiles to medical devices; anywhere that requires miniaturization, sensing, actuating, communication, and processing is our specialty.

Get in touch to find out how you can get more out of your MEMS today.